Wholesale Price China Special Wax in Agriculture and Forestry to Jeddah Manufacturer

Short Description:

Product Detail

Product Tags

Wholesale Price China Special Wax in Agriculture and Forestry to Jeddah Manufacturer Detail:

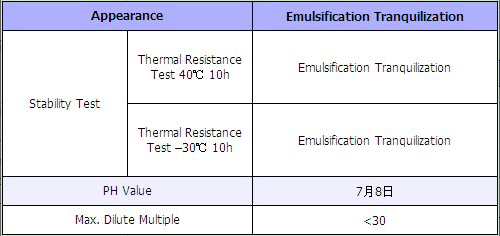

(1)YNE4 Series Special Molding Moisturized Wax for Fruit Trees

In order to protect fruit trees and shrubs from desiccation during winter dormancy or transportation or to keep moisture in summer drought, Special Molding Moisturized Wax is spayed on the surface of trees, forming the protecting film in surface of trees. The film has some adequate micro pore that could efficiently reduce the losses of moisture in the surface of the trees, and it simultaneously ensures physiological respiration of the trees.

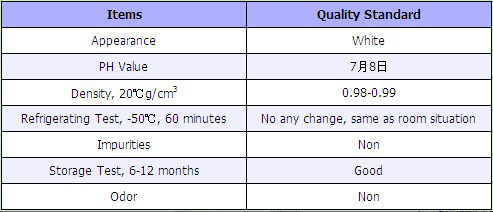

(2) YNE5 Series Special Preventing Frostbite Wax for Trees

(3) In large northern areas of our country, the winter season is severe cold and the spring season is more heavy windy.

The early winter and the late spring’s frost are quite disadvantage to young plant, the weather is particularly abnormal coldness after spring comes, and frequently injures these trees. As a result young plant is cold death. YNE5 Series Special Preventing Frostbite Wax for Trees not only has anti-freezing effect on trees but also well effect on anti-sprouting etc. Spraying on branches and leaves of trees can make exuberant growth of foliage.

Product detail pictures:

We always believe that one's character decides products' quality, the details decides products' high-quality ,together with the REALISTIC,EFFICIENT AND INNOVATIVE crew spirit for Wholesale Price China Special Wax in Agriculture and Forestry to Jeddah Manufacturer, The product will supply to all over the world, such as: Sevilla , Germany , Sri Lanka , Our company follows laws and international practice. We promise to be responsible for friends, customers and all partners. We would like to establish a long-term relationship and friendship with every customer from all over the world on the basis of mutual benefits. We warmly welcome all old and new customers to visit our company to negotiate business.

A clone of my Lil Esquire of 1967 that used a Rand LR3. The new Tobe Actuator makes it possible to fly Galloping Ghost with a modern radio system. Tobe and Phil G are the designers of the Actuator and there is a great single channel group at https://singlechannellersreunited.co.uk/. For more information contact Jay Mendoza at jaymen@pacbell.net.