Online Exporter U-1A00 thermal wax actuator for thermostatic automatic water drain valve for Rio de Janeiro Manufacturer

Short Description:

Product Detail

Product Tags

Online Exporter U-1A00 thermal wax actuator for thermostatic automatic water drain valve for Rio de Janeiro Manufacturer Detail:

1. Operation Principle

The Thermostatic Wax that has been sealed in shell body induces expansion by a given temperature, and inner rubber seal part drives its handspike to move under expansion pressure to realize a transition from thermal energy into mechanical energy. The Thermostatic Wax brings an upward movement to its handspike, and automatic control of various function are realized by use of upward movement of handspike. The return of handspike is accomplished by negative load in a given returned temperature.

2. Characteristic

(1)Small body size, occupied limited space, and its size and structure may be designed in according to the location where needs to work.

(2)Temperature control is reliable and nicety

(3)No shaking and tranquilization in working condition.

(4)The element doesn’t need special maintenance.

(5)Working life is long.

3.Main Technical Parameters

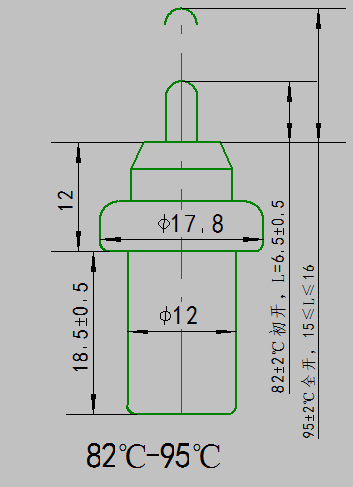

(1)Handspike’s height may be confirmed by drawing and technical parameters

(2)Handspike movement is relatives to the temperature range of the element, and the effective distance range is from 1.5mm to 20 mm.

(3)Temperature control range of thermal wax actuator is between –20 ~ 230℃.

(4)Lag phenomenon is generally 1 ~ 2℃. Friction of each component part and lag of the component part temperature cause a lag phenomenon. Because there is a difference between up and down curve of traveling distance.

(5)Loading force of thermal wax actuator is difference, it depends on its’ shell size.

Product detail pictures:

Our corporation has been specializing in brand strategy. Customers' gratification is our greatest advertising. We also source OEM company for Online Exporter U-1A00 thermal wax actuator for thermostatic automatic water drain valve for Rio de Janeiro Manufacturer, The product will supply to all over the world, such as: Hongkong , Hyderabad , Switzerland , Our R&D department always designs with new fashion ideas so we could introduce up-to-date fashion styles every month. Our strict production management systems always ensure stable and high quality products. Our trade team provides timely and efficient services. If there are any interest and inquiry about our products, please contact us in time. We would like to establish a business relationship with your honored company.

Double Acting:0°-90°

Output torque(0.5Mpa.Nm):16.6-2695

Operating Temperature:-20℃-+80℃

Connect apeopple’s thread:1/8

V8 arrangement of new Piezo Linear Motor – Nanometer Precision Positioning for Industrial Applications. More: https://www.pi-usa.us/products/Piezo_Motors_Stages/Linear-Motor-Precision-Positioning.php#NEX

When large optics, detectors or camera set-ups in industrial

applications need to be positioned with nanometer precision, it can be advantageous to cut the actuator power one the fine positioning process is complete. If an actuator cannot hold position without a continuous current draw, heat and thermal effects may have negative side effects on performance of the system.

PI’s PICMAWalk piezo linear motor uses 8 PICMA® piezo actuators arranged in a V-shape similar to a classical V8 engine to achieve high push/pull and holding forces along with nanometer precision.

The space-tested PICMA® actuators are highly reliable, providing 60N (13lbs) holding force and 50N (11 lbs) push/pull force. The maximum velocity is 15mm/sec (0.6 inch/sec).

Loads up to 5kg (11lbs) can be positioned with nanometer precision.

Open and Closed-Loop Designs

The units are available with 3 standard travel ranges from 25 to 100mm in both open and closed-loop configurations. The closed-loop models incorporate a high-precision incremental encoder with nanometer resolution. The calculated piezo-mechanical resolution is better than 1/10 nanometer.

For maximum precision and reliability, the piezo actuators are integrated in a solid-state flexure guiding system, free of stiction and friction. Flexure elements combine high stiffness and load capacity. They do not require maintenance or lubricants, are 100% vacuum compatible, function in a wide temperature range, and are intrinsically wear-free.

In addition to the standard models, custom designs for OEMs are available, facilitated by the modular design.