Lowest Price for Special Wax in Agriculture and Forestry for California Manufacturers

Short Description:

Product Detail

Product Tags

Lowest Price for Special Wax in Agriculture and Forestry for California Manufacturers Detail:

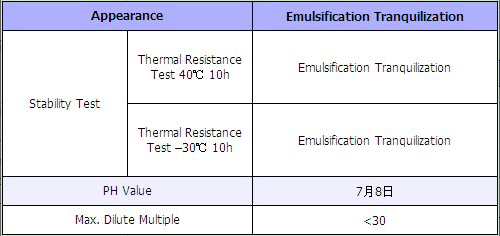

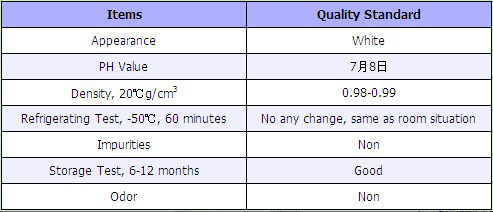

(1)YNE4 Series Special Molding Moisturized Wax for Fruit Trees

In order to protect fruit trees and shrubs from desiccation during winter dormancy or transportation or to keep moisture in summer drought, Special Molding Moisturized Wax is spayed on the surface of trees, forming the protecting film in surface of trees. The film has some adequate micro pore that could efficiently reduce the losses of moisture in the surface of the trees, and it simultaneously ensures physiological respiration of the trees.

(2) YNE5 Series Special Preventing Frostbite Wax for Trees

(3) In large northern areas of our country, the winter season is severe cold and the spring season is more heavy windy.

The early winter and the late spring’s frost are quite disadvantage to young plant, the weather is particularly abnormal coldness after spring comes, and frequently injures these trees. As a result young plant is cold death. YNE5 Series Special Preventing Frostbite Wax for Trees not only has anti-freezing effect on trees but also well effect on anti-sprouting etc. Spraying on branches and leaves of trees can make exuberant growth of foliage.

Product detail pictures:

We've been proud with the significant shopper fulfillment and wide acceptance due to our persistent pursuit of top of the range both of those on solution and repair for Lowest Price for Special Wax in Agriculture and Forestry for California Manufacturers, The product will supply to all over the world, such as: Munich , Sudan , Botswana , We sincerely hope to cooperate with customers all over the world, if you would like to have more information, please kindly contact us, we are looking forward to building up a great business relationship with you.

https://www.1aauto.com/1A/four-wheel-drive-parts/Chevy/Tahoe/1AFWA00001?utm_source=YouTube&utm_medium=description&utm_campaign=videodesc&utm_term=JpHn9gRXVXw

1A Auto shows you how to repair, install, fix, change or replace a failing, defective, leaking or corroded 4WD front axle vacuum actuator. This video is applicable to the 95, 96, 97, 98, 99, Chevy Tahoe or GMC Yukon.

https://www.partselect.com/PS557945-Whirlpool-4389102-Electronic-Control-Boards-emitter-and-receiver.htm?SourceCode=15Click here for more information on this part, installation instructions and more.

This particular Electronic Control Board is specific to Whirlpool manufactured brands including Admiral, Estate, Inglis, Kenmore, KitchenAid, Roper, Maytag, Crosley, Jenn-Air, Hardwick, Magic Chef, Amana, Glenwood, and Caloric. To find a specific to your model, visit https://www.PartSelect.com.

If your fridge is having any of these symptoms, then replacing the Electronic Control Board could solve your appliance problem.

1) The ice maker will not stop making ice

2) The ice maker will not make ice

3) The ice maker seems to have stopped working properly

PartSelect® Part Number: PS557945

Whirlpool OEM Part Number: 4389102

Tools used for this repair/replacement:

1) Philips Screw Driver

Get model-specific repair help from PartSelect.com. Learn how to troubleshoot, diagnose and repair your appliance with user-generated installation instructions, hundreds of step-by-step repair videos, and our Instant Repairman. If you’ve got an appliance problem, we can help https://www.partselect.com/Instant-Repairman.htm