Good Quality U-1A00 thermal wax actuator for thermostatic automatic water drain valve to Naples Importers

Short Description:

Product Detail

Product Tags

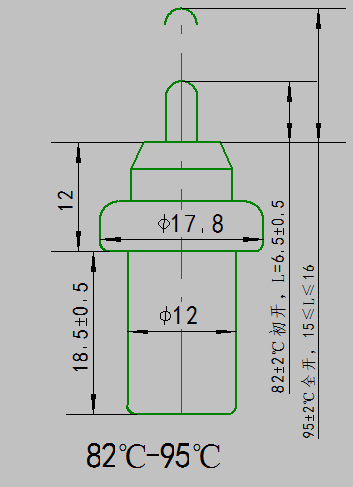

Good Quality U-1A00 thermal wax actuator for thermostatic automatic water drain valve to Naples Importers Detail:

1. Operation Principle

The Thermostatic Wax that has been sealed in shell body induces expansion by a given temperature, and inner rubber seal part drives its handspike to move under expansion pressure to realize a transition from thermal energy into mechanical energy. The Thermostatic Wax brings an upward movement to its handspike, and automatic control of various function are realized by use of upward movement of handspike. The return of handspike is accomplished by negative load in a given returned temperature.

2. Characteristic

(1)Small body size, occupied limited space, and its size and structure may be designed in according to the location where needs to work.

(2)Temperature control is reliable and nicety

(3)No shaking and tranquilization in working condition.

(4)The element doesn’t need special maintenance.

(5)Working life is long.

3.Main Technical Parameters

(1)Handspike’s height may be confirmed by drawing and technical parameters

(2)Handspike movement is relatives to the temperature range of the element, and the effective distance range is from 1.5mm to 20 mm.

(3)Temperature control range of thermal wax actuator is between –20 ~ 230℃.

(4)Lag phenomenon is generally 1 ~ 2℃. Friction of each component part and lag of the component part temperature cause a lag phenomenon. Because there is a difference between up and down curve of traveling distance.

(5)Loading force of thermal wax actuator is difference, it depends on its’ shell size.

Product detail pictures:

We support our purchasers with ideal high-quality merchandise and significant level company. Becoming the specialist manufacturer in this sector, we now have received loaded practical encounter in producing and managing for Good Quality U-1A00 thermal wax actuator for thermostatic automatic water drain valve to Naples Importers, The product will supply to all over the world, such as: Mali , Madras , Porto , We rely on high-quality materials, perfect design, excellent customer service and the competitive price to win the trust of many customers at home and abroad. 95%products are exported to overseas markets.

IF YOU WATCHED PT 1 ALREADY SKIP TO 2:18 This is still only a part of the complete video that I am putting together about control panels and control wiring.https://www.electricalindustrynetwork.com This panel was wire off the cuff,no wiring diagram,no help from any one and I have done this to help people that want to learn more more about control wiring. Not intended for those of you that know how to wire a panel already. This is a work in progress and if I get enough people interested I can rewire to fit a lot of demonstrations.Please be helpful in your comments.

Fuel Filter Replacement in a nutshell:

1) Replace every 20K miles (I do mine every 10K with oil change).

2) Have the right filter for your housing.

3) Engine OFF! Remove Upper Sound Absorber Panel.

4) Water Separator Service (1 Screw Plug, 1 Washer Seal)

a. Remove Screw Plug and old Washer Seal with Torx T30 bit.

b. Siphon water at bottom of Filter Housing from top of housing – A.K.A Fuel Sump.

c. Siphon enough fuel to avoid spillage when Housing is opened.

d. Reinstall Screw Plug with New Washer Seal. Torque 3 Nm (27 in-lb).

5) Fuel Filter Replacement (1 Filter, 2 Seals on Filter, 2 Seals in Housing)

a. Remove 5 Torx T30 Bolts and lift off Upper Filter Housing with lines undisturbed.

b. If you see any amount of metal particles TAKE THE CAR TO A PROFESSIONAL! You have a major issue.

c. Pull out old Filter and Seals in Housing.

d. Clean as necessary Lower Filter Housing by Siphoning out remaining Water/Fuel.

NOTE: Removal of Lower Filter Housing is not a requirement. So long as you remove any contaminants found at the bottom of the canister by other means.

e. Install New Filter and New Seals.

f. FILL CANISTER WITH CLEAN FUEL to help purge air. (approx. 650 ml or 22 oz) —OR— Use VAG-COM to operate fuel pump from fuel tank to prime the fuel system (the air will be sent back to the tank to vent) SEE VAG-COM STEP BELOW (7).

g. Reinstall Upper Filter Housing and secure with 5 Bolts. Torque 5 Nm (44 in-lb).

6) Reinstall Upper Sound Absorber Panel.

7) If you have VCDS/VAG-COM, operate fuel pumps to purge air from Filter Housing.

8) Otherwise, Start Engine & try to run it at 2K RPM for at least 30 seconds. If Engine shuts down, restart engine (this method is not preferred. it is bad for your High Pressure Fuel Pump).

NOTE: Turning key to turn on Accessories does not turn on the fuel pumps, from what I have read, only when the key is turned to Ignition (Engine Start).

————————————–

A visual aid to what to expect when replacing the Fuel Filter on the 2009 VW Jetta TDI (A5 – CBEA ).

I used as a reference the Bentley Publishers VW Jetta Service Manual (2005-2010) as well as a couple of very good write-ups which can be found at the following links. Many thanks to those who took the time to document and share the information at these links.

https://www.myturbodiesel.com/1000q/a5/2009-2010-VW-TDI-fuel-filter.htm

https://www.tdiblog.com/tdi-do-it-yourself/replacing-fuel-filter-a5-brm-cbea/#more-148

I obtained the Mann Fuel Filter from IDPARTS.COM (formerly TDIPARTS.COM), UPS Ground Shipping was free with them. Amazon.com also offers the same Mann Fuel Filter for those who are exclusive to Amazon.